These are the main differences between water well drill bits

The principle of selecting the water well drilling bit:

Stratigraphic conditions: different stratigraphic hardness, degree of fragmentation, and other factors determine the selection of drill bit.

Drilling purpose: Different drilling purposes require different drill bits, such as coring drilling, directional drilling, and so on.

Drilling fluid performance: The performance of the drilling fluid affects bit wear and life.

The Rig Performance: Factors such as the power and torque of the drilling rig will also influence the choice of the drill bit.

Toothed Wheel Drill Bit:

Features: Good abrasion resistance, suitable for hard rock drilling.

Classification: According to the number of teeth, tooth type, material and so on are divided into various types.

Scope of application: Hard rock layer, medium hard rock layer, etc.

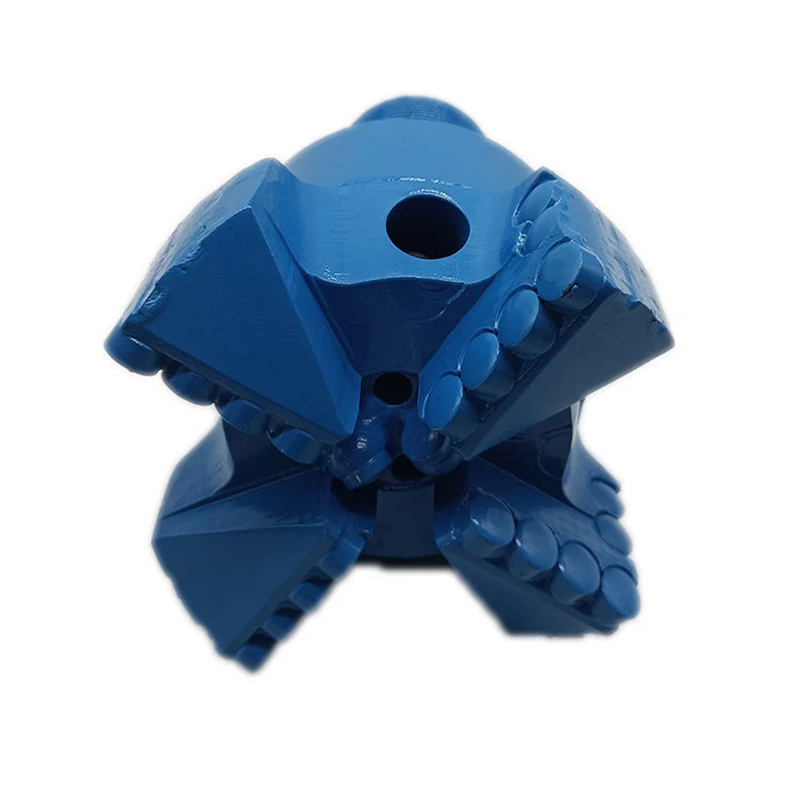

PDC Drill Bit:

Characteristics: Fast drilling speed, strong cutting force, suitable for soft and hard rock formations.

Classification: According to the number, arrangement and shape of PDC blades, they are divided into various types.

Scope of application: Soft rock formation, medium-hard rock formation, hard rock formation.

Diamond Drill Bits:

Characteristics: Fast drilling speed, high accuracy of hole diameter, suitable for hard rock formation and stratum junction.

Classification: According to the diamond particle size, concentration, bonding method, etc. are divided into various types.

Scope of application: hard rock formations and stratigraphic junctions.

Comments

Post a Comment